Suspended ceilings can be installed with exposed grid or unexposed grid with a seamless finish or featured joints. Ramco Hilux boards provide both type of ceilings, i.e. Hilux boards cut to size 595x595mm or 595 x 1195 mm and laid into the "T" grid, made of galvanized steel with precoated steel at the bottom (Exposed grid system), or Hilux boards screw fixed under side of G.I. frame work and finished with seamless joints (Unexposed grid). The ceiling can be single or double layer, depending on the specific requirements. The Hilux boards cut to size 2’x2’can also be fixed as featured joints by providing gap in between the boards and finished with beadings or moldings. Curved ceilings can also be formed with a little change in its frame work and board.

A non-load bearing system which includes Hilux boards fixed to the G.I frame is mostly used to provide a suspended false ceiling with seamless finish. It is very easy and fast to erect. It can easily accommodate all type of light and air conditioning fittings.

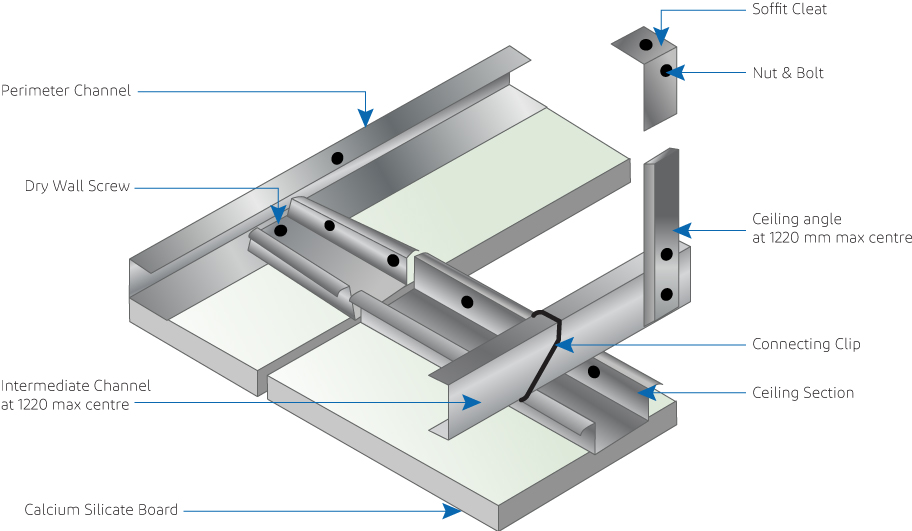

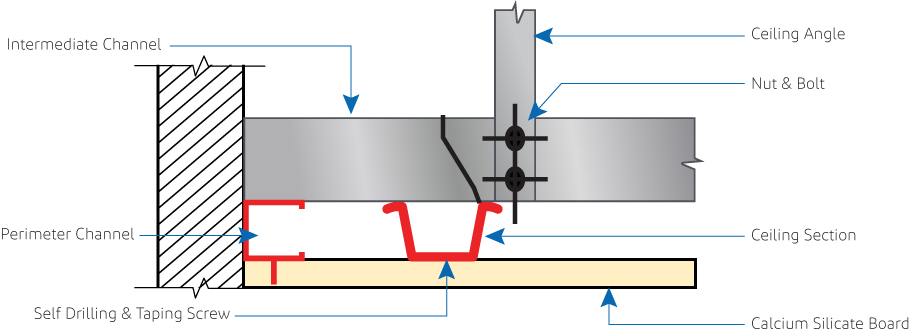

First of all ceiling level is marked on to the wall / partition as per the drawing, leaving a scope for board thickness. G.I. Perimeter channel is fixed to the perimeter of the wall/ partition with nylon sleeves and wood screws (38 mm long) at 450mm centers, at the above level. Intermediate channel is suspended from the soffit at 1220mm centers with the help of rawlplug, soffit cleat and the ceiling angle, in one direction. Ceiling sections are attached to the intermediate channel, across to it, by connecting clips at 610mm centers. The length of ceiling sections or intermediate channels can be increased by providing an overlap of 6”and are screw fixed at 4 places.

Ramco Hilux tapered edge boards of size, 6’x4’ are fixed to the underside of ceiling sections by 25mm long self-drilling and taping screws having Phillips head with under head cutter at 200mm c/c. The screws should be 15mm away from the edges and 40 mm from the corners. The square edges of the boards are made tapered (40x1.5mm) or chamfered by 4x3mm at site before fixing. The joints between boards are staggered in brick work style to make the ceiling rigid and properly aligned to the required level.

Hilux board joints are finished with specially formulated jointing compound and 48mm wide, fiber mesh tape to get seamless finish.