Structural Steel Cladding

The building regulations require certain elements of structure to have fire resistance for a specific minimum period of

time. The amount of fire protection to achieve this depends on the following:

- 1. Duration of fire resistance specified

- 2. Type of protection used

- 3. Shape and size of the steel section

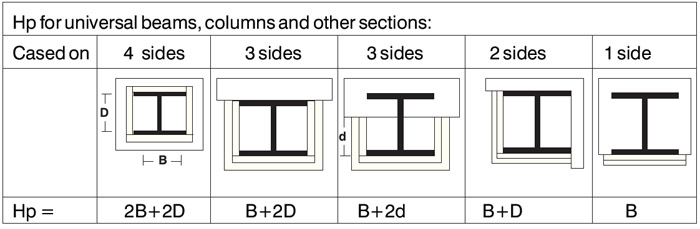

The degree of fire protection depends on the Hp/A section factor for the steel section. The Hp/A factor are a

function of the area of the steel exposed to the fire and the mass of the steel section. The higher the Hp/A, the faster the steel

section heats up, so the greater thickness of fire protection material required.

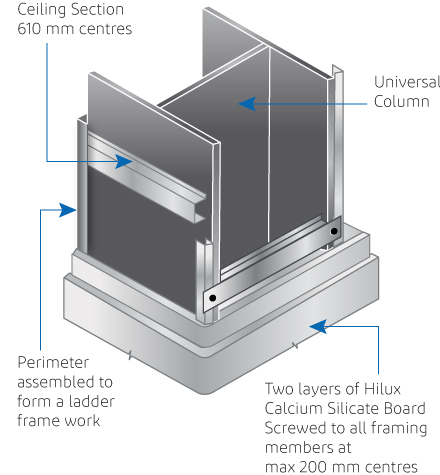

Box Protection

In the case of box protection, Hp is the sum of the inside dimensions of the smallest possible rectangular or square encasement

of the steel section (except for circular hollow sections) where a steel section abuts, or is built into a fire resisting wall or

floor, the surface in contact with or the surface within the wall or floor, is ignored when calculating Hp. However the value A

is always the total cross- sectional area of the steel section.

Encasements following the profile of the steel section will generally have a higher Hp/A value than a box encasement (except

circular hollow sections). The serial size and mass per meter of most steel sections are available in tables with steel

manufacturers which also give Hp/A values calculated for 3 or 4 sided box protection

Note: For partially exposed members, the A value is still the total cross sectional area of the section being protected.

Example-1:

Steel Beam, Serial Size 457 x 191 x 98 kg/m to be encased on three sides

- Serial size: 457 mm x 191 mm

- Actual size: 467.4 mm (D) x 192.8 mm (B)

- Hp: B+2D = 192.8+467.4+467.4 = 1127.6 mm = 1.1276 m

- A: 125.3 cm² = 0.01253 m²

- Hp/A: 1.1276 / 0.01253 = 89.99 = 90 m-1

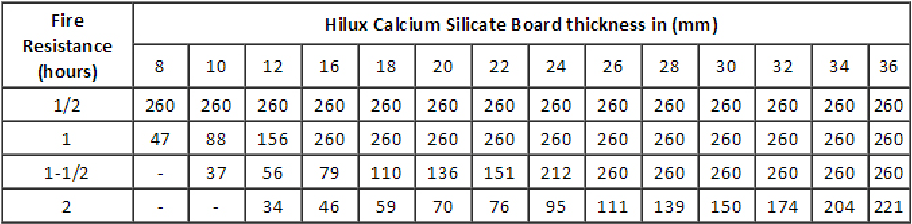

From this, the required thickness of the Hilux boards can be found for different period of fire protection by using the following Tables:

Table-1

showing Hilux boards thickness (mm) required as per Maximum Hp/A section factor (m-1) for up to 2 hours of fire

protection in accordance with the requirements of BS-476: Part 21 and AS 1530: Part -4

Maximum Hp/A section factor (m-1)

Partially exposed members

Where columns or beams are partly built into or are in close contact with wall or floors, then account can be taken of the protection afforded

to the steel work by the wall or floor. In the case of masonry work then this will give protection to the adjacent surface of the steel work so that

for the purpose of determining the heated perimeter, Hp, this should be taken as only that which is exposed.

Installation

Four sides encasement

- Determine the thickness of the board to be used as per the Hp/A section factor for the given fire rating.

- Cut two pieces from the board to match the size of the width of the column.

- G.I. angles25x25x0.80mm is screw fixed to these cut boards at their longitudinal edges, using self-taping screws at 200mm centers.

- These are placed vertically on both sides of the column, facing each other.

- Cut another two pieces two suite the length of the column/beam + twice the thickness of the boards used.

- Screw these new pieces to already vertically placed boards (fixed with G.I. angle) with self-taping screws at 200mm centers.

- If the height of the casing exceeds the length of the board a horizontal member is provide to support the edges of the boards.

Three sides encasement

- In this case G.I. Angle 25x25x0.80 mm thick is fixed to the wall or partition on the both sides of the column.

- A piece of board is cut to size of opposite side and G.I.angle is screw fixed on the longitudinal edges of the cut piece.

- This is placed vertically with just opposite side of the column.

- Another piece cut from the board (Actual measurement + thickness of the boards used) is screw fixed to both, the angle fixed to the

wall/ partition and the angle of vertically placed board at 200mm centers with self-taping screws.

- Another piece cut from the board as above is screw fixed to other side of the column, to both, the angle fixed to the wall/ partition and the

angle of vertically placed board at 200mm centers with self-taping screws.

Two sides encasement

- G.I. angles 25x25x0.80 are fixed to the walls/partition on both sides of the column with metal fasteners at 450mm centers.

- A piece of board is cut to size of one side and an angle is screw fixed to one of the edge of this cut piece at 200mm centers.

- This is placed against the column, keeping the angle side opposite to the wall. Other edge of this board is screw fixed to the already fixed

angle (with the wall / partition) at 200mm centers with self-taping screws.

- Another piece cut to size is screw fixed to the remaining side of the column at 200mm centers with self-taping screws.

- Jointing and finishing can be done as usual.

One side encasement

- G.I. angle is fixed to the both sides of the wall / partition with metal fasteners at 450mm centers.

- Hilux board of suitable size is screw fixed to the angles at 200mm centers. Jointing and finishing can be done as usual.